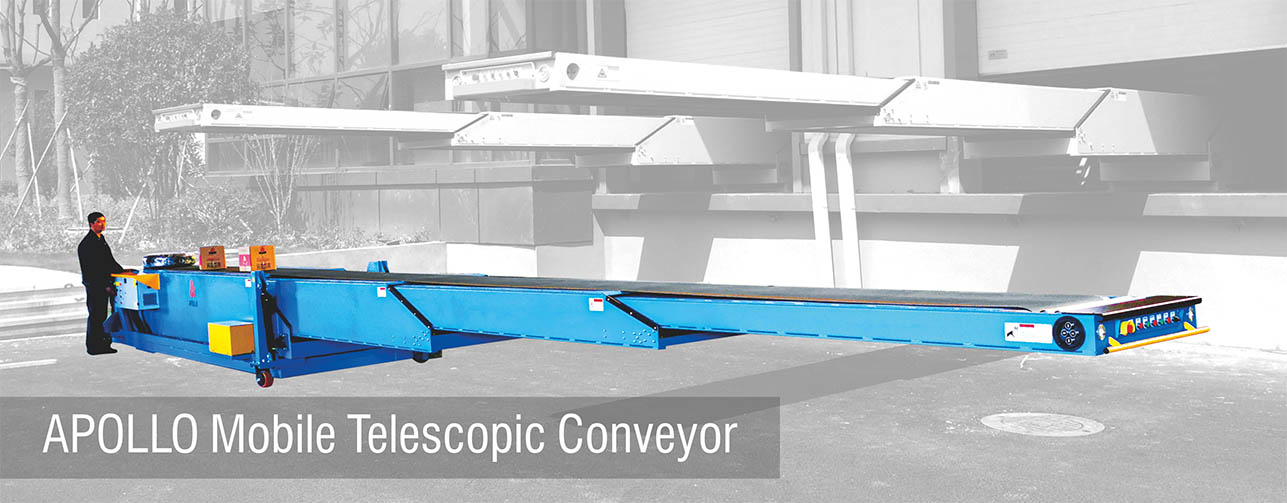

Fixed Telescopic Belt Conveyor for Trucks / Containers Easy Loading or Unloading

Industry Applications

Telescopic Belt Conveyor is automated conveyor equipment for easy loading and unloading. Virtually any industry with heavy shipping and receiving needs will reap significant rewards from implementing a telescopic belt conveyor solution. Widely used in E-commerce, Third party logistics, Food, Beverages, Pharmaceuticals, Clothes, Furniteure and FMCG etc.

●Suitable for variety of vehicle/ truck/container

●Conform to ergonomic operating conditions

●Fast loading and unloading

●Simple, safe and reliable

●Easy maintenance

●Loading capacity: 60kg/m

●Reduce manual handling, reduce labor intensity

●High efficient operation up to more than 2000 PPH

●Standard work to make loading or unloading orderly

●Save labor more than 2/3 based on original loading way

●Minimum the accident during loading, even zero incidence

●Improve the working environment

APOLLO Telescopic Belt Conveyor provides the highest level of productivity for large volume, shipping and receiving applications for any type factory or distribution center. Its biggest advantage is providing an ergonomic operating conditions, the operator could adjust the conveyor to achieve a perfect position via buttons to control extending and retracting, loading or unloading easily and efficiently, all the actions will be real-time feedback to the operator by electronics. Automate your loading and unloading areas and convey a variety of products from large or small cartons to loose bags and tires.

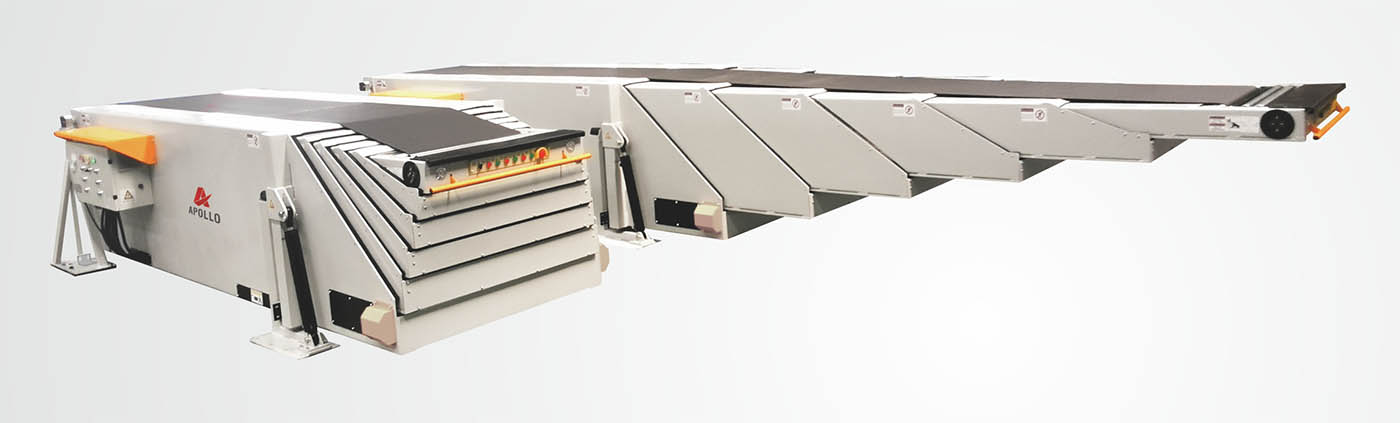

All key components use the top famous brnad only, like SEW motor, Siegling motor, the electrical compontens are Schneider or Siemens to ensure the most reliable stability and reduce the failure rate to the greatest extend. All of our telescopic conveyors feature a VFD controlled belt drive system providing smooth transitions from belt starts and stops at speeds up to 40m/minute. They also include a VFD controlled extension drive providing smooth operation when extending and retracting the conveyor.

Frame use hugh quality carbon steel, get the advanatges of impact resistance, fatigue resistance and high strength. Steel structure design, using the finite element analysis method and optimize the stress structure, so that the whole stress get balanced and extend the using life of machine. At the same time, the maximum extebsion length and minimum retraction length are guaranteed. Maximum sections APOLLO can do is 6 sections with 16 meters extension.

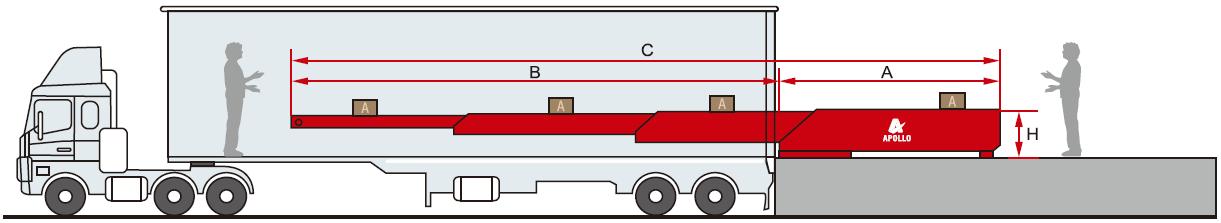

| Model | Sections | Total length C(mm) | Retracted length A(mm) | Extension length B(mm) | Height(mm) | Belt width(mm) | Installation way |

| A3-6+8 | 3 | 14000 | 6000 | 8000 | 800 | 600/800/1000 | Fixed Type |

| A3-7+9.5 | 16500 | 7000 | 9500 | 800 | 600/800/1000 | Fixed Type | |

| A4-5+10 | 4 | 15000 | 5000 | 10000 | 900 | 600/800/1000 | Fixed Type |

| A4-6+12 | 18000 | 6000 | 12000 | 900 | 600/800/1000 | Fixed Type | |

| A4-7+14 | 21000 | 7000 | 14000 | 900 | 600/800/1000 | Fixed Type | |

| A4-8+16 | 24000 | 8000 | 16000 | 900 | 600/800/1000 | Fixed Type | |

| A5-6+15 | 5 | 21000 | 6000 | 15000 | 950 | 600/800/1000 | Fixed Type |

| A5-7+18 | 25000 | 7000 | 18000 | 950 | 600/800/1000 | Fixed Type | |

| A6-4.5+13 | 6 | 17500 | 4500 | 13000 | 1050 | 600/800/1000 | Fixed Type |

| A6-5+16 | 21000 | 5000 | 16000 | 1050 | 600/800/1000 | Fixed Type |

Frequently Asked Questions:

4 directions buttons, easy operation

Equip with tower light, easy to see machine status

Anti-clamping roller, avoid the risk of clamping hands for operators

The gap between each section is small and the brush is installed for safe use

Simens PLC control system gets convenient remote maintenance and after-sales service

Schneider VFD to adjsut speed, quality stable

SICK sensor at front to prevent goods fall (optional)

Side guides for align goods (optional)

Wireless remote control (optional)

Cut steel plate by laser

Bending

Welding

Polishing

Install belt

Assembly

Powder coating

Forming frame

Wiring

Buttons test

Finished products

At user site

Our innovation is at your service

Consumer behavior has changed, supply chains have not. Let's talk today to find perfect design and make your loading or unloading more easy, more safe, more efficiency.