High Efficiency Spiral Conveyor For Vertical Transfer Between Different Floors

Industry Applications

Spiral Conveyor is a lifting or descending equipment with good stability and suitable for wide range of goods. Mainly used for the transmission of goods between the height difference. Spiral Conveyor can supply the temporary storage for goods, or up and down continuous handling. Widely used inn in E-commerce, beverages, tobaccos, postal service, newspaper industry, printing, food, pharmaceutical, cloth, electronic products and other industries.

Carbon steel and stainless steel both available

High efficient for vertical transfer

Maximum speed up to 60m/min

Maximum capacity 50kg/m

Single driven, easy control

Small space occupuation

Low frication structure, stable and reliable

Low noise running, quiet and comfortable

Long performance life, able to 7*24 hours running

Built-in protection for loose chain, stuck goods/overload protection

APOLLO Spiral Conveyors are based on a new and innovative technology, offering many features and benefits. APOLLO uses low friction slat and rolling friction bearing, which has the characteristics of low wear and low noise. APOLLO adopts modular parts and the inserted slat by injection mounding, which has good toughness and strength. The production is the full assembly process, each part is standard part, each size is unique, workers cannot interfere with the size during assembly.

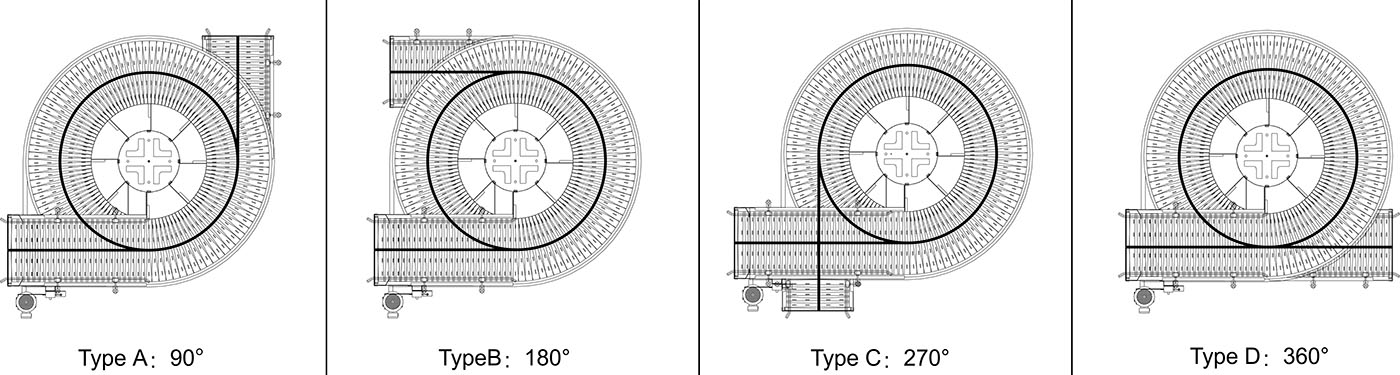

Spiral Conveyor can be combined with the infeed and oufeed conveyors to compose a complete set of lifting system to meet the vertical transportation needs for large logistic centers. Multiple units superposition can get higher height, APOLLO also allows different floors multiple entry, efffectively reduce the cost of vertical transportation. APOLLO adopts modular design which allows multiple specifications available to meet different size of good, also brings easy installation, can deliver goods in fully assembled or disassembled to meet the site condition of different users.

| Model | Slat Width | Abutting Conveyor Width | Run Speed | Rated Load | Diameter | Machine Height | Frame Material |

| 5030-500 | 500mm | 580mm | ≤40m/min ≤60m/min | ≤50kg/m | φ 2200mm | Single unit≤10m ( if higher than 10m, can superpose multiple units) | Carbon steel Stainless steel 304 |

| 5030-650 | 650mm | 730mm | ≤40m/min ≤60m/min | ≤50kg/m | φ2550mm | Single unit≤10m ( if higher than 10m can superpose multiple units) | Carbon steel Stainless steel 304 |

Frequently Asked Questions:

Total 23m consist of 3 units

Height 9.5m

Height 7m

Total 13.6m consist of 2 units

Height 8m

Height 17.8m

Center column fabricate

Spiral plate assembly

Slat track installation

Lifting for running test before delivery

Noise test

Install slat

Our innovation is at your service

Consumer behavior has changed, supply chains have not. Let's talk today to find perfect design and make your vertical transfer more easy, more safe, more efficiency.