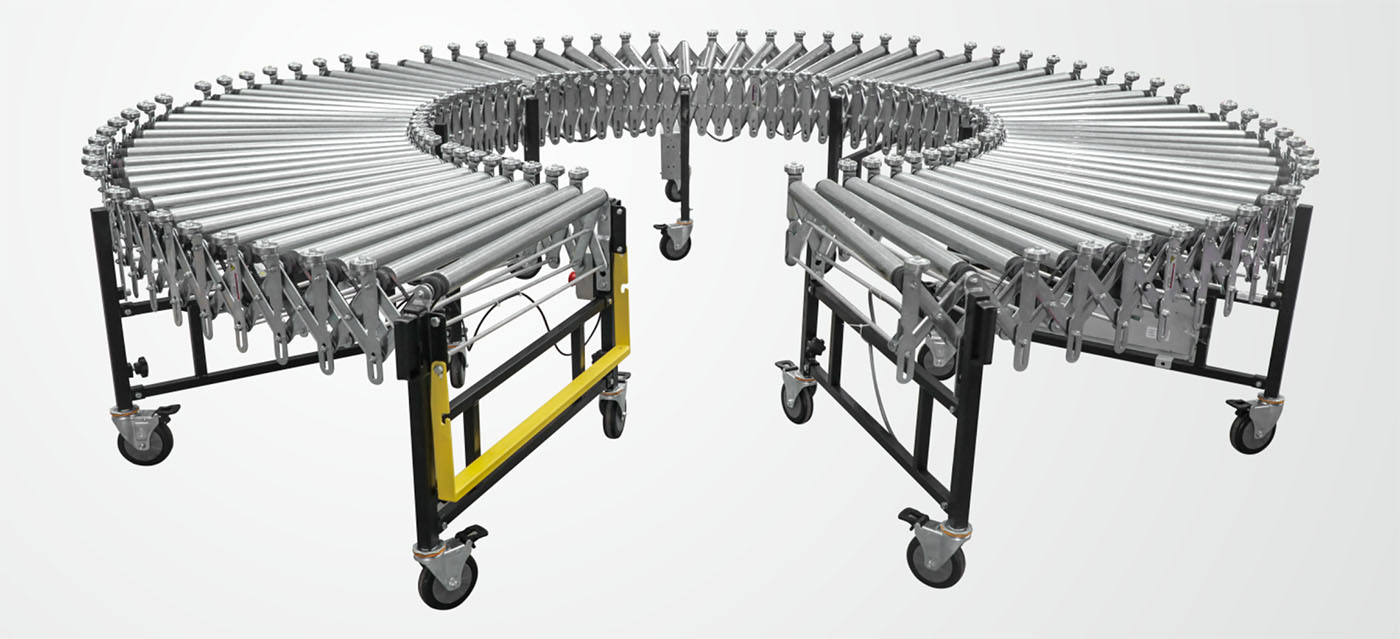

Flexible Roller Conveyor For Easy Transportation of Goods in Warehouse

Industry Applications

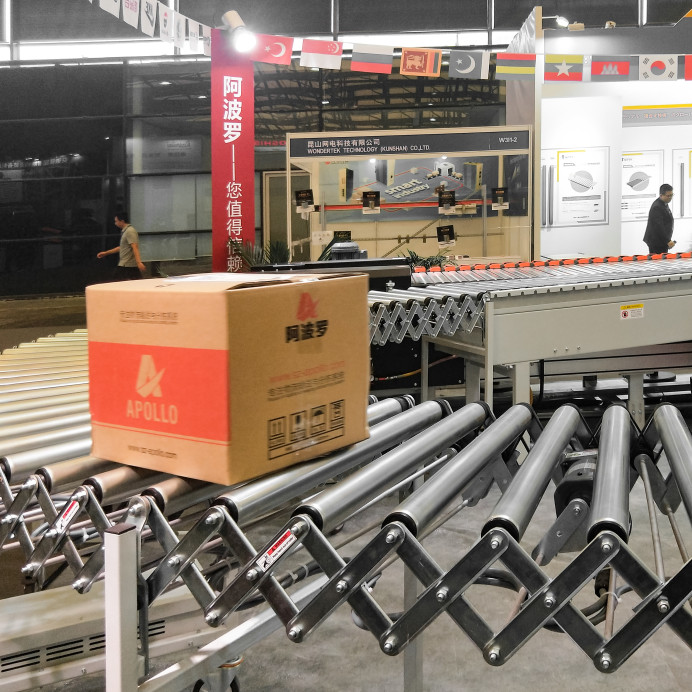

Flexible Roller Conveyor is suitable for flexible and changeable occasion. Each conveyor section consists of rollers that are mounted on a series of axles attached to a frame. A motor-driven belt or shaft turns the rollers, so these conveyors do not require a manual push or slope to move loads down the line. They convey items at a controlled speed with even spacing and are typically used in warehousing, manufacturing, package handling, and distribution applications.

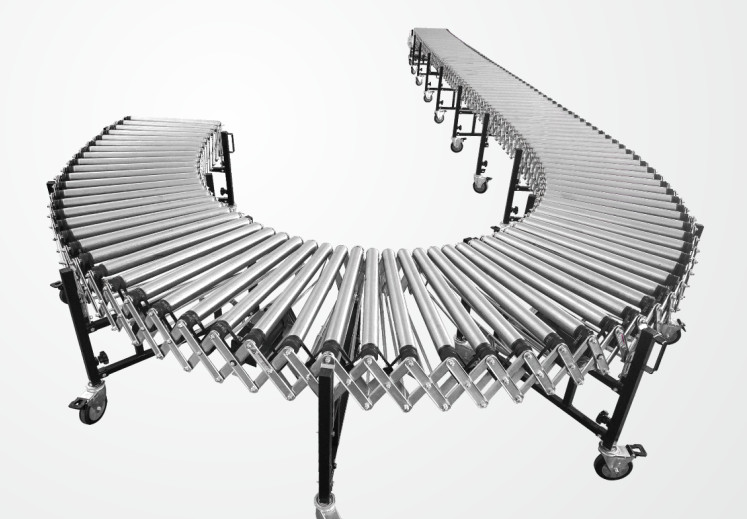

● Suitable for flexible and changeable sites

●Cartons convey smoothly around curves and bends

●No incline/decline required to convey cartons from one end to the other

●Shorten time to handle goods, reduce labor intensity, reduce damage to goods, improve work efficiency

●Can be used alone, also can be combined with other transport equipments

●Driven by motors, goods can be conveyed automatially

●Directly used on ground after stretching

●Types of goods to handle: cartons, plastic trays, products in flat bottom, fabric rolls, tires etc.

●Roller: carbon steel galvanized or stainless steel

●Capacity: 50~ 60 kg/meter

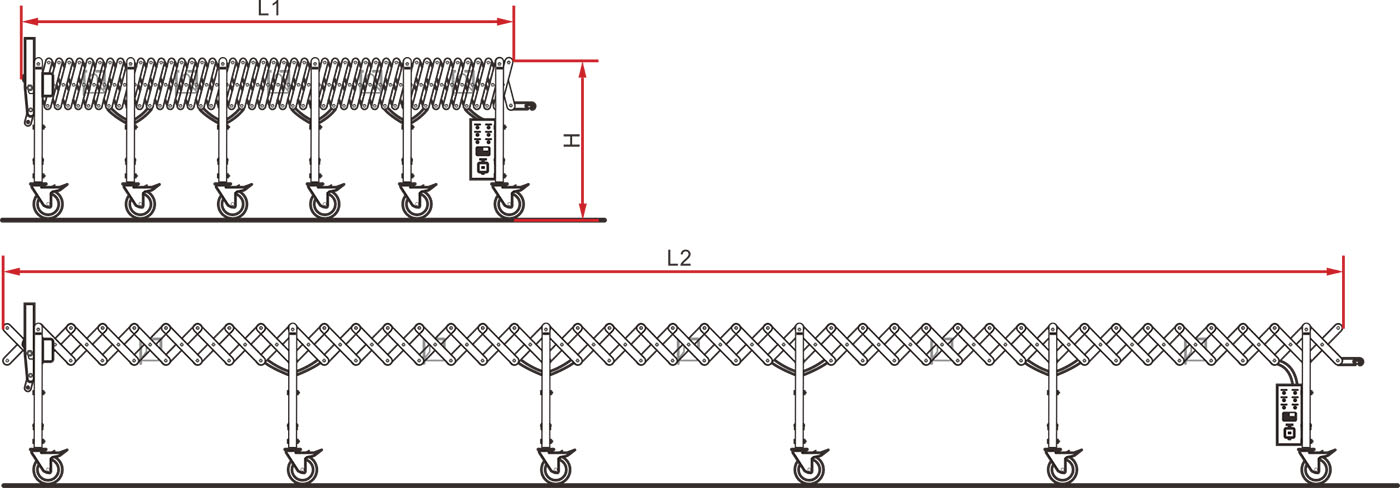

Flexible powered roller conveyors can take your conveyor solution to the next level of productivity and efficiency. APOLLO Flexible Roller Conveyor can be used alone, also can be combined withother conveying equipment. These flexible roller conveyor units are on casters so they can be rolled into the back of a semi-truck to load or unload boxes or rolled over to your order fulfillment area for packaging. Flexible roller conveyor can expand the length as your needs while in use, also can collapse to about half or less of the expanded size when you want to store them.

Powered roller conveyors have extendable, flexible frames and are commonly used for loading and unloading trailers. The frames can stretch, curve, and contract to change the length and shape of the conveyors. These conveyors can flex around corners, service multiple dock doors. When not in use, valuable space can be saved by retracting the conveyor to its smallest footprint.

| Model | Extended length L2(mm) | Retracted length L1(mm) | Height H(mm) | Roller width (mm) | Frame width (mmm) | Roller material | Side guards |

| R-4500 | 4780 | 1870 | 700-1000 | 600/800 | 670/870 | Galvanized / Stainless Steel | Optional |

| R-6500 | 6940 | 2700 | 700-1000 | 600/800 | 670/870 | Galvanized / Stainless Steel | Optional |

| R-8000 | 8000 | 3120 | 700-1000 | 600/800 | 670/870 | Galvanized / Stainless Steel | Optional |

| R-10000 | 10000 | 3950 | 700-1000 | 600/800 | 670/870 | Galvanized / Stainless Steel | Optional |

| R-12000 | 12000 | 4780 | 700-1000 | 600/800 | 670/870 | Galvanized / Stainless Steel | Optional |

| R-15000 | 15600 | 6030 | 700-1000 | 600/800 | 670/870 | Galvanized /Stainless Steel | Optiona |

Frequently Asked Questions:

Equip with Start/Stop/Emergeny Stop at end of conveyor

Each section uses one micro motor

Electrical control cabinet to control the running of conveyor

Can curve as your needs

Able to connect with other conveyors for conitunous transfer

Load capacity up to 50kg/m

Our innovation is at your service

Consumer behavior has changed, supply chains have not. Let's talk today to find perfect design and make your materials transportation more easy, more safe, more efficiency.