High Speed Sliding Shoe Sorter For Express Company or E-Commerce

Industry Applications

Sliding Shoe Sorter can handle various kinds and sizes of packages by varying the amount of shoes. APOLLO Sliding Shoe Sorter is a tested and proven technology throughout a wide range of industries and applications, including Clothes, Express Parcels, E-commerce, FMCG, Pharmaceuticals, Furniture, Food and Beverage etc.

●Advanced and reliable sorting technology: can handle a wide range of product sizes, weights and shapes, cost effective and easy to control

●High sorting efficiency: easily meet the demand of high throughput

●Gentle handling: flexible diverter angle

●Operating environment: quiet, low noise

●Durability: stable and reliable

●Convenient maintenance, reduce downtime and high uptime

●The completely closed platform structure effectively prevents products and divert from falling f rom the gap

●Materials handle: Carton, Circulating box, Tire, Parcels

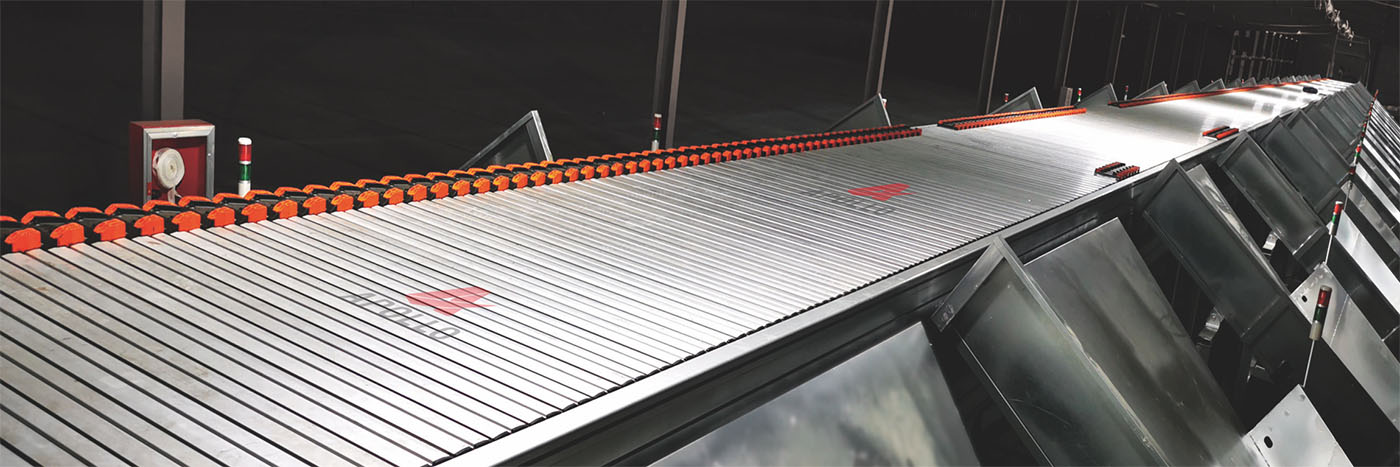

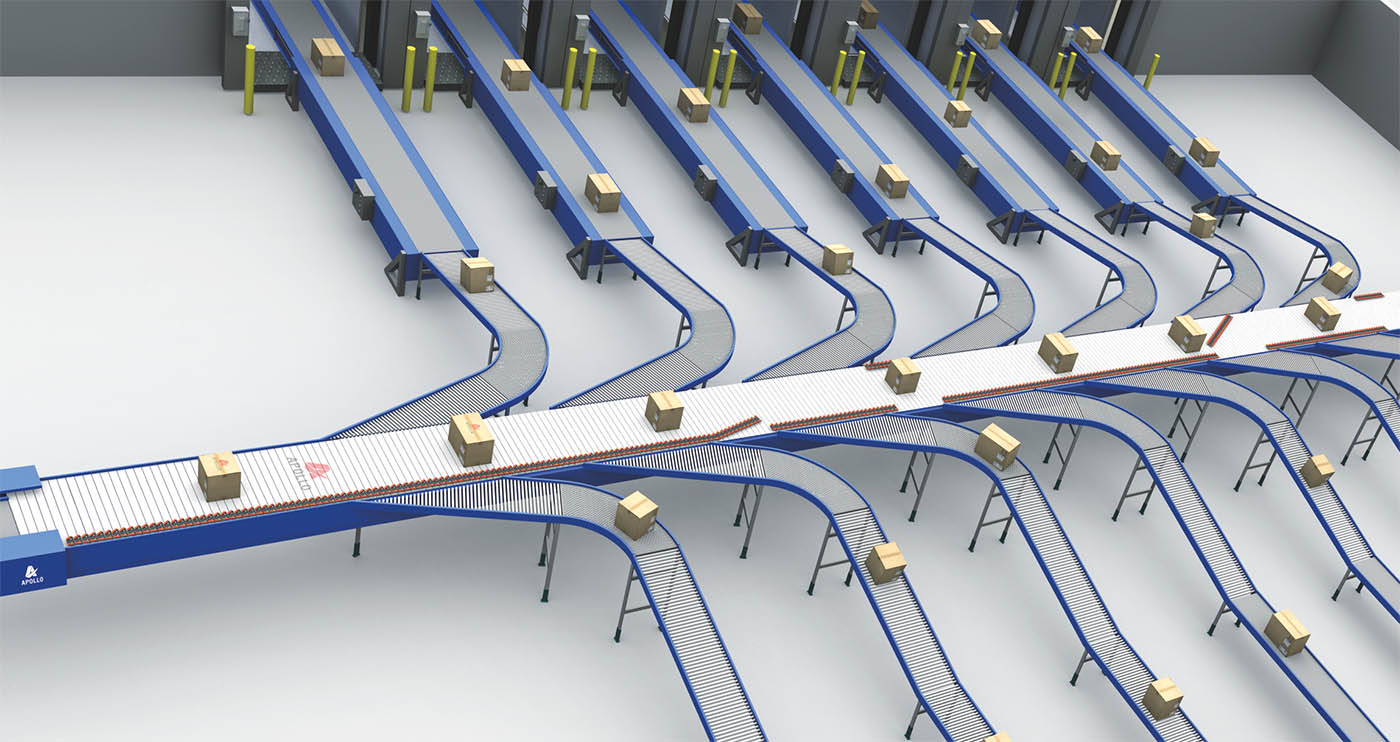

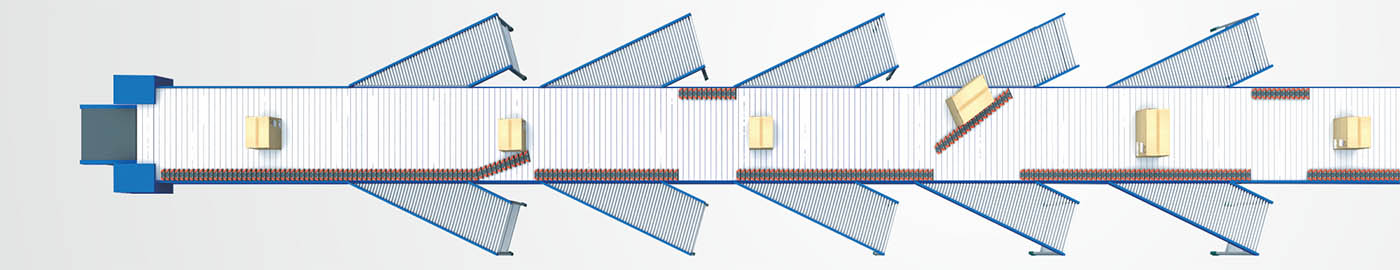

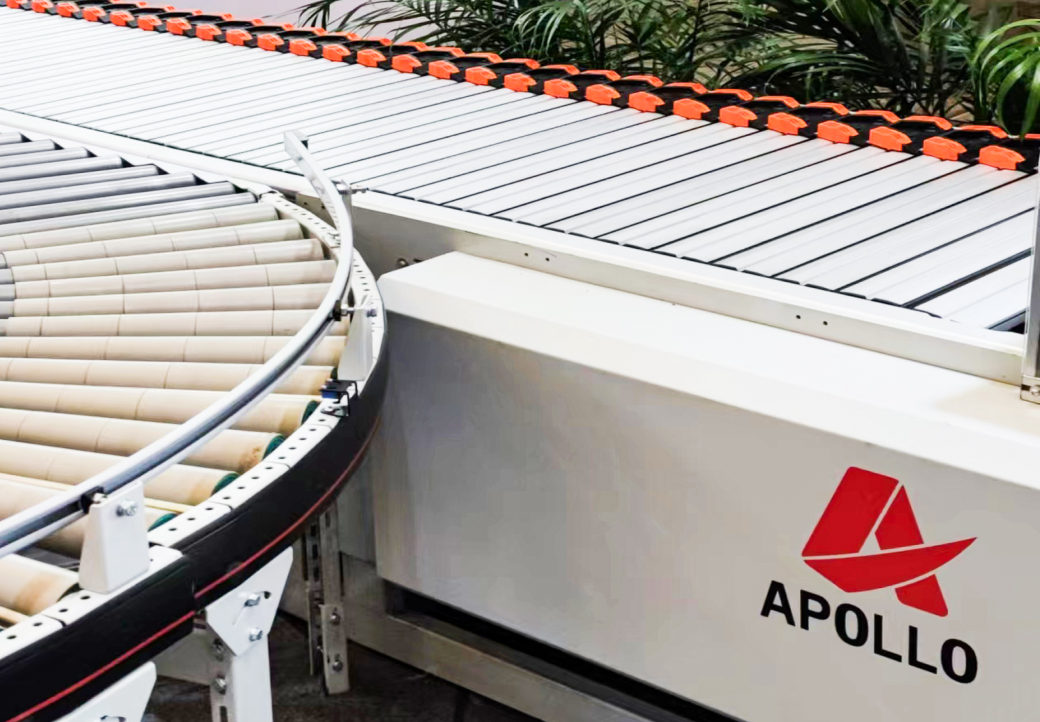

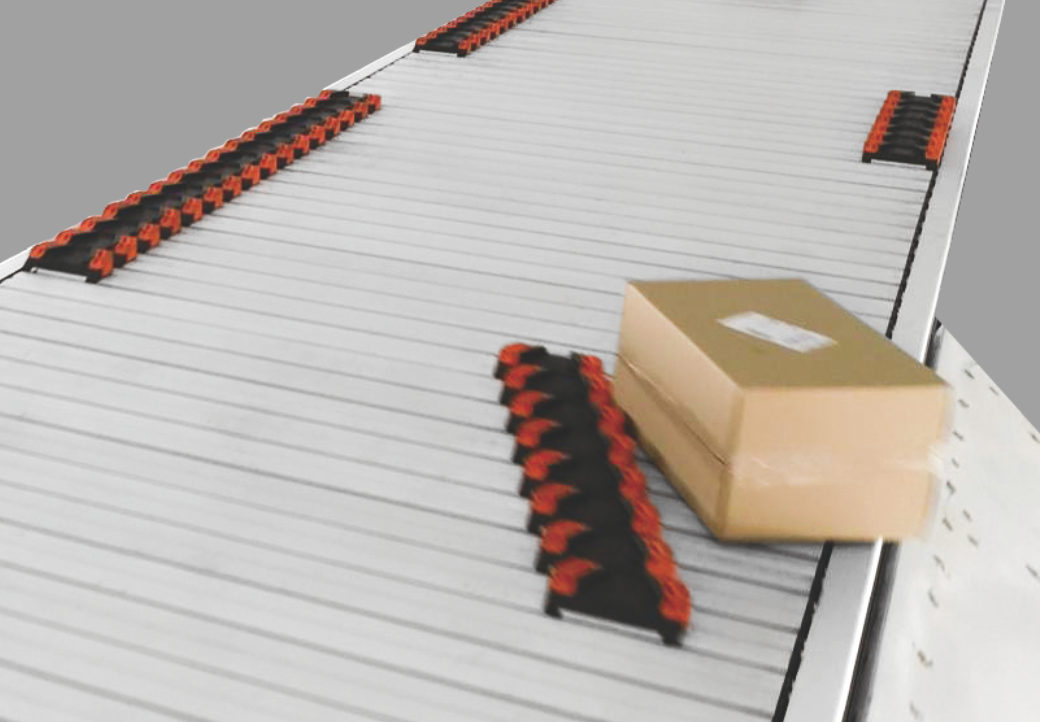

Sliding Shoe Sorter is a high throughput, precise diverting sorter which can reliably track and gently sort a wide range of parcels along a linear sortation. APOLLO Sliding Shoe Sorter is modularly designed, which composed of a bed of uniform slats that creates a virtual flat conveyor, ideal for conveying a variety of parcels. Each slat has a sliding "shoe" attached. Shoes are aligned to one side of the parcel. When a parcel reaches its assigned sorting exit, several shoes are electronically activated to slide in the intended direction, guiding the parcel to its destination. The precision by shoes controlled allow them to gently push parcels toward a lane or chute in a fluid diagonal movement.

All types of cartons and packaged goods can be accurately sorted to either side of the sorter at high rates of speed. Sliding Shoe Sorter can transport products smoothly, gently, quietly, with noise levels equal to or below 75dB. The use of soft polyurethane creats a small gap between the infeed and outfeed conveyor. Modular component design is adjustable and can be extended or reconfigured to meet changing requirements of user. Overall maintenance is minimal due to simple construction of steel and aluminum components. The closed deck construction allows the sorter to run clean and without gaps.

Sliding Shoe Sorter can be used to sort a variety of product size, shape and weight. For fragile or easily damaged products, a smooth and gentle movement is required from the sorter to exit, then Sliding Shoe Sorter is an ideal option, unilateral or bilateral sorting both available, APOLLO can customize sorting direction according to the special system requirements.

| Item | Specification | Remark |

| Sorter type | Shoe sorter | 9030/9025 Type |

| Parcels type | Carton, Circulating box, Tire, Parcels | / |

| Parcels size | Min:L100×W50×H5mm Max:L1800×W1000×H1000mm | / |

| Parcels weight | 0.1-50kg | Max: 100kg |

| Sorting throughput | 4000-8500 parcels/hour | / |

| Running speed | Max.3m/s | To be advised based on parcels information |

| Main conveyor length | Max:150m | Length can be customized |

| Sorting direction | One side/ Double side sorting | / |

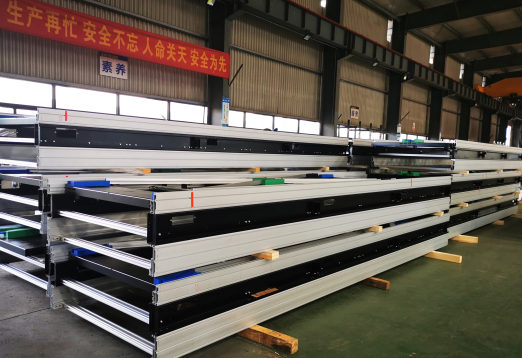

| Frame material | Carbon steel | Color can be customized |

| Machine height | 800mm-1500mm | Height can be customized |

| Working voltage | 3 phase 380V.415V.480V | Voltage can be customized |

| System software & DWS | Apollo control software | Can customize as use's operation demands |

Frequently Asked Questions:

Barcode scanning area

Top famous brand Cognex to read barcode

5 sides scanning

Software

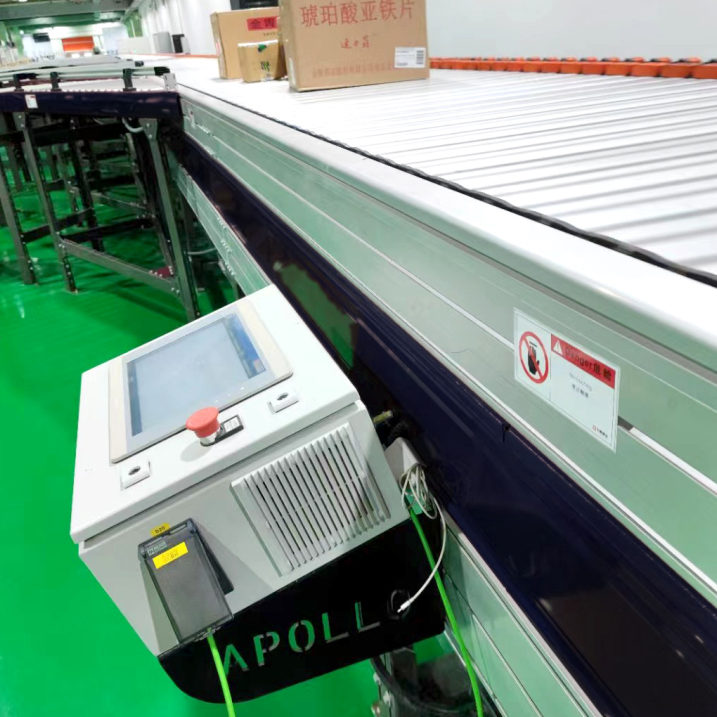

HMI for checking running status

Eletrical control cabinet

Sliding shoe for sorting

Infeed conveyor

Outfeed conveyors

Frame fabricate

Assembly main parts

Installation of Shoe Sorter

Debug control software and power-on test

Inspection before delivery

Finished product

Noise test

Running test

Our innovation is at your service

Consumer behavior has changed, supply chains have not. Let's talk today to find perfect design and make your sorting more easy, more safe, more efficiency.